AMHIGLEY BUILDERS BLOG: Mass Timber and the Future of Sustainable Construction

AMHIGLEY BUILDERS BLOG - AMHigley employees give their technical expertise and insights on the construction industry

This month’s blog featuring Shreya Garad explores mass timber products and how it is changing the construction industry as a sustainable alternative to traditional materials. Additionally, Shreya focuses on how the United States is behind the curve when it comes to mass timber fabrication and utilization. Shreya obtained her M.S. in Construction Management from Michigan State University, with her thesis focusing on Mass Timber titled; Impact of Change Orders on the Cost Performance of Mass Timber Construction Projects.

Mass Timber and the Future of Sustainable Construction

Shreya Garad | Project Engineer | 1 Year with AMHigley

Shreya Garad | Project Engineer | 1 Year with AMHigley

In recent years, the construction industry has witnessed a shift towards more sustainable building materials and practices. Among these materials, mass timber has emerged as a frontrunner, offering a promising solution for environmentally conscious construction projects.

Mass timber is a structural product made from dimensional veneer or lumber that is used as an alternative to conventional materials like steel and concrete. The products are created by bonding together large solid wood panels or framing elements to form structural components. The sourcing of mass timber utilizes the least amount of carbon when compared to conventional construction materials like concrete or steel.

It has been used widely in commercial markets such as hospitality, multi-family housing, higher education, and convention centers/pavilions. These markets allow the more design centered elements of using mass timber products to be highlighted in a space.

There are multiple different types of mass timber products. Glue laminated timber (Glulam) and Cross laminated timber (CLT) are the most extensively used types of mass timber products.

Glue Laminated Timber

Glue Laminated Timber  Cross Laminated Timber

Cross Laminated Timber

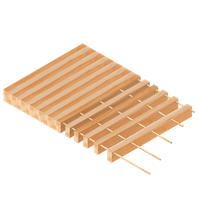

Apart from that, dowel laminated timber, nail laminated timber, and mass plywood are few of the others. These products offer exceptional strength, stability, and fire resistance while utilizing sustainably sourced wood.

Dowel Laminated Timber (photo credit to www.thinkwood.com)

Dowel Laminated Timber (photo credit to www.thinkwood.com)

Nail Laminated Timber (photo credit to www.thinkwood.com)

Nail Laminated Timber (photo credit to www.thinkwood.com)

Mass Plywoood

Mass Plywoood

Not only are mass timber products a more sustainable choice but they have many other advantages. Since mass timber products are prefabricated, this leads to faster erection times which can aid the overall project schedule. Similarly, smaller crew sizes for erection lead to lesser safety liability.

Mass timber structures are lighter in weight and lead to smaller foundations. Due to the tensile properties of wood, the seismic stability of mass timber structures is better compared to conventional construction materials, which is beneficial to the safety and longevity of a building. Additionally, right on time delivery saves material storage and temporary protection costs.

One of the most significant advantages of mass timber is its ability to store carbon dioxide. Wood acts as a carbon sink, capturing and storing atmospheric carbon throughout its lifespan. By incorporating mass timber products into buildings, it effectively reduces carbon emissions associated with traditional construction materials.

Mass timber has been around in the construction industry since the 1990’s, used mostly in European countries. It has slowly become used within the United States within the last decade. There are major roadblocks for increased mass timber production in the United States. Firstly, supply chain issues with the United States can be greatly improved. The supply does not meet the demand leading to procurement from other countries. Since mass timber is newer in the United States, building codes are more restrictive in a few states. This then limits use of mass timber products. This requires local authorities needing to be actively involved and convinced to curb the restrictions.

However, in the United States, it is more widely accepted in the Pacific Northwest. There are more manufacturing facilities available within that region of the country. Apart from the United States, it is widely used and manufactured in Canada, Germany, and Austria.

Currently compared to alternatives, the mass timber material costs are higher. However, schedule time reduction and smaller crew size should be considered for comparison. Labor is the most expensive cost in any project and smaller crews lead to savings on labor costs.

If the United States can expand their production and use of mass timber products, the construction industry could see a massive increase in more sustainable construction and could lead to even more innovations within the mass timber industry.

Mass timber offers a compelling solution that combines structural integrity, aesthetic appeal, and environmental stewardship. By harnessing the potential of mass timber products, we can pave the way towards a more sustainable and resilient built environment.